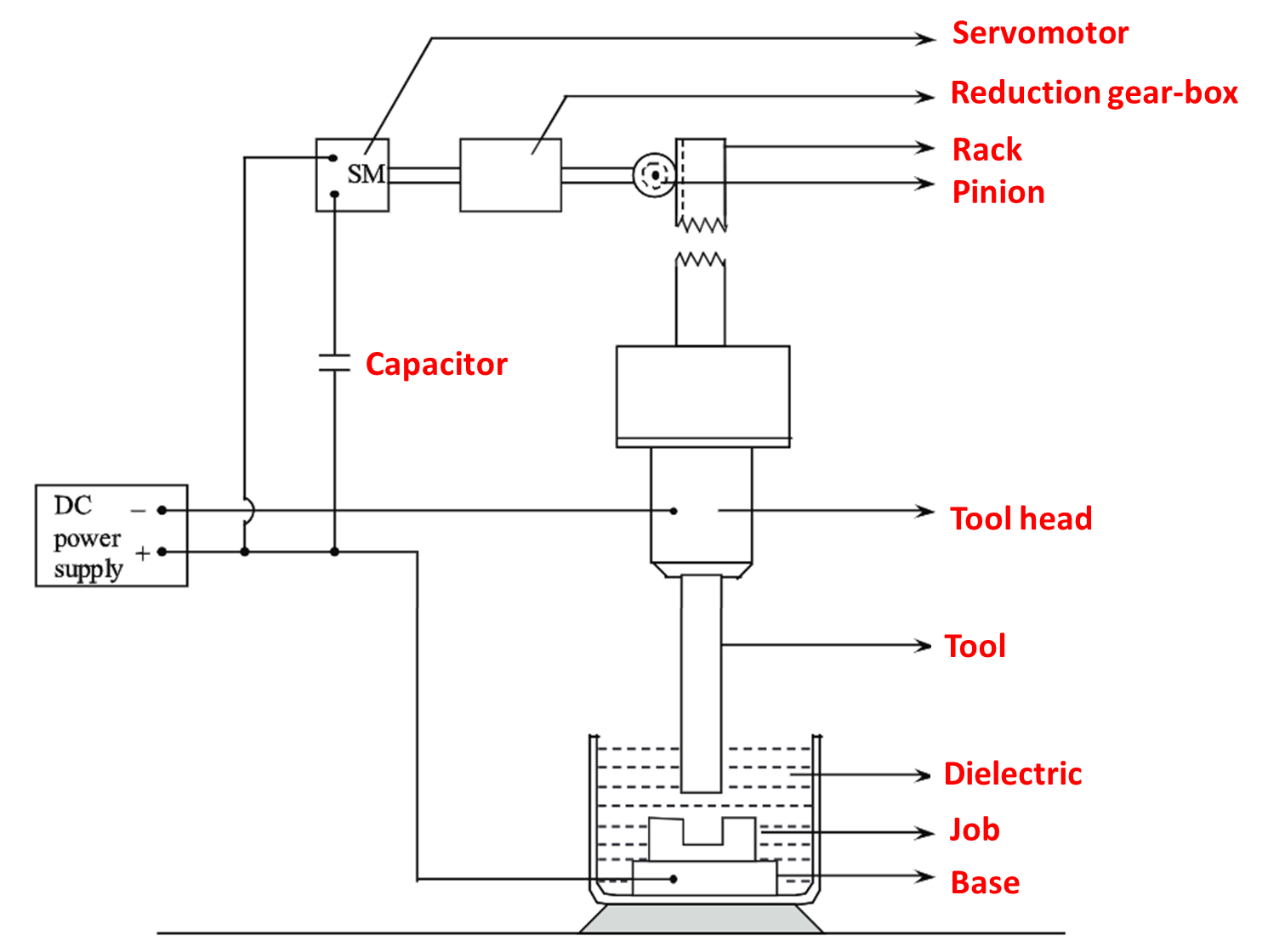

electrical discharge machining diagram

1 Electrical Discharge Machining EDM GOPINATHG MECHANICAL 2. Electrical discharge machining is a quick and unique way to create accurate deep small holes drilling in materials regardless of their hardness.

Electrical Discharge Machining How Edm Machine Works

Edm discharge machining electrical principles.

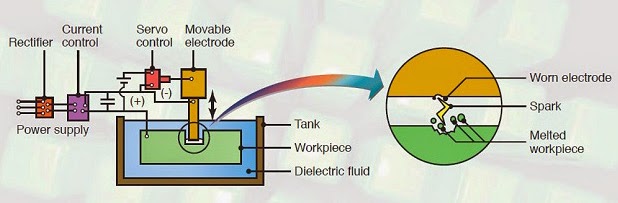

. The hole drilling process involves using a. Electrical discharge machining 1. The component material is melted due to heat generated from the spark as in case of conventional EDM.

Banu and Ali 201 6. The history of EDM Machining Techniques goes as far back as the 1770s when it was discovered by an English Scientist. 9 Images about The Principle of Electrical Discharge Machining Is So Simple Its Role.

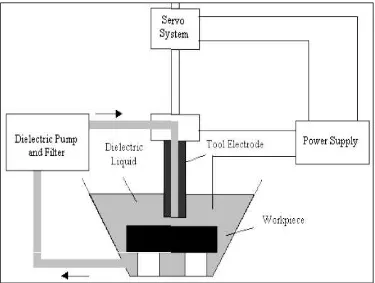

The di-electric fluid which is a non-conductor of electricity is forced through the gap under pressure. In this article we will discuss about the electric discharge machining EDM- 1. The Principle of Electrical.

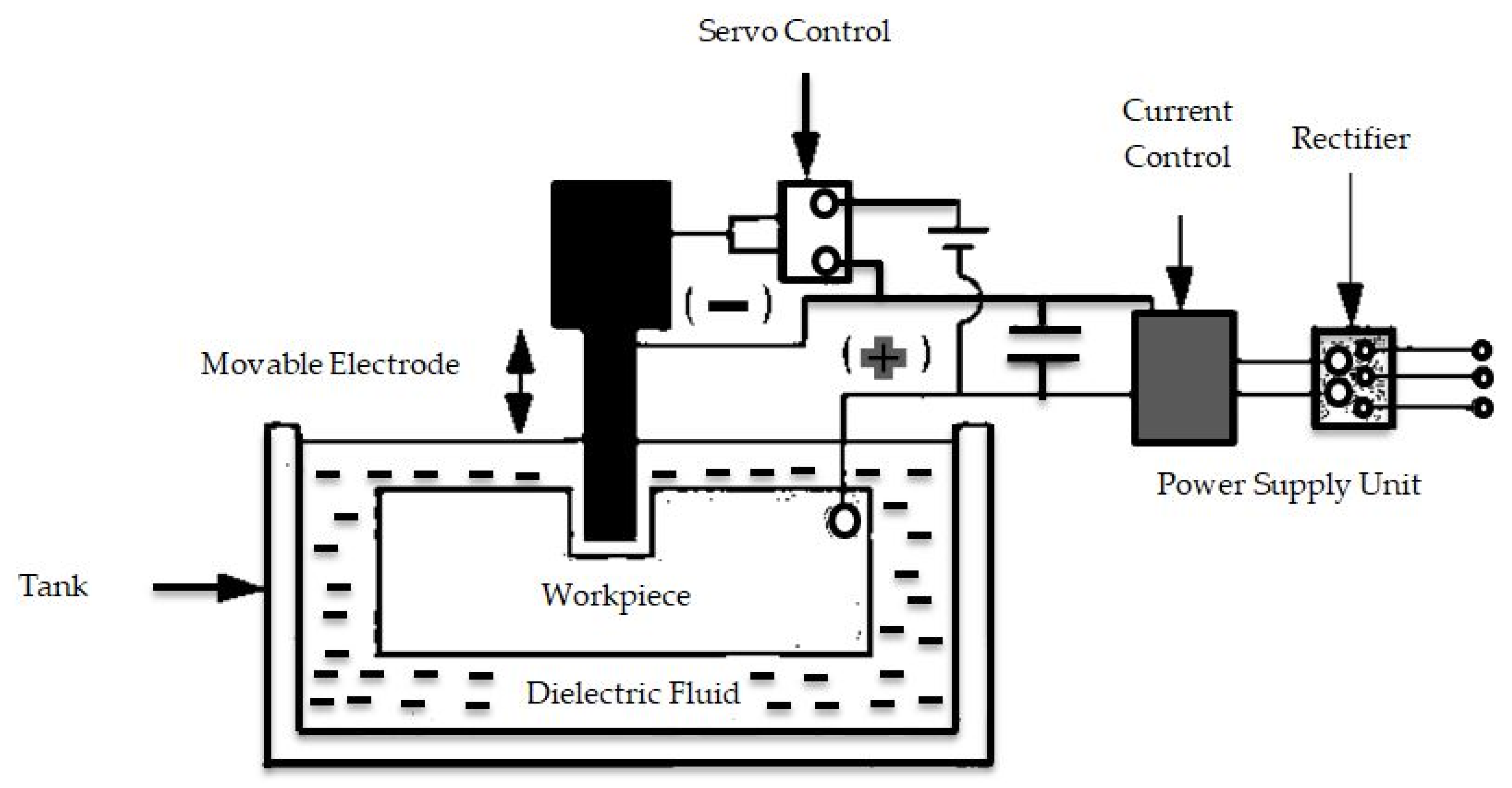

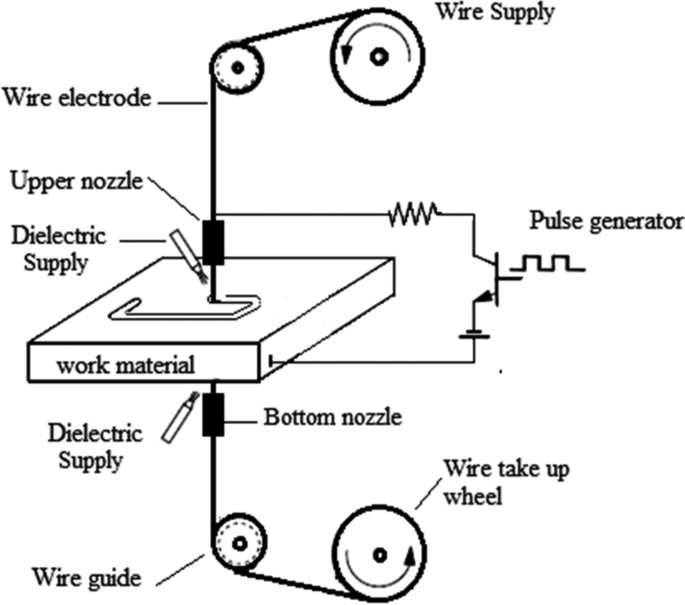

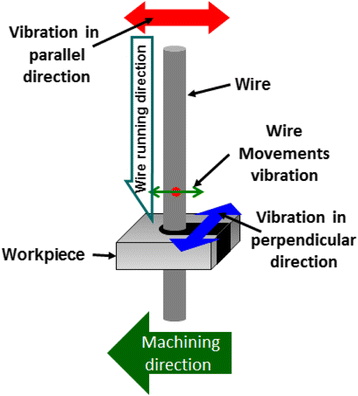

The Principle of Electrical Discharge Machining Is So Simple Its Role. Introduction to Electric Discharge Machining EDM 2. Wire electrical discharge machining WEDM uses a metallic wire to cut or shape a workpiece often a conductive material with a thin electrode wire that follows a precisely programmed.

When DC power is applied the fluid in the. 11 Images about How is classification of Non-traditional Machining done. However Electrical Discharge Machining was not fully taken.

Removes any electrically conducting material by high frequency sparks that arc through a dielectric fluid flowing between the negatively charged workpiece and. Electric discharge machining diagram. 2 Sometimes it is referred to as spark machining spark eroding.

Electrical discharge machining EDM is a non-traditional machining process based on removing material from a part by means of a series of repeated. Schematic diagram of micro-EDM of non-conductive zirconia using a dhesive copper assisting electrode 38. Download scientific diagram Electrical Discharge Machining from publication.

A study of discharge pulse energy in electrical discharge machining In electrical discharge machining. This process is also named spark erosion machining or spark over initiated discharge machining as the removal of metal occurs due to erosion caused by the electric. How is classification of Non-traditional Machining done.

Mechanics of EDM 3. In this machining method a predefined gap between the tool wire and the.

Current Research Trends In Electric Discharge Machining Edm Review

What Is Electrical Discharge Machining Edm Process Diagram Advantages Applications Electricalworkbook

Figure 1 From Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Electrical Discharge Machining An Overview Sciencedirect Topics

Mrr Improvement In Sinking Electrical Discharge Machining A Review

Schematic Diagram Of Electric Discharge Machining Process Download Scientific Diagram

Ultra Precision Electrical Discharge Machining Service

Micromachines Free Full Text Recent Advances And Perceptive Insights Into Powder Mixed Dielectric Fluid Of Edm Html

What Is Electric Discharge Machining Quora

Wire Edm Machining For Extreme Accuracy Explained Mellowpine

Performance Evaluation Of Electric Discharge Machining Of Titanium Alloy A Review Journal Of Engineering And Applied Science Full Text

Electrical Discharge Machining Principle Working Equipment S Advantages And Disadvantages With Diagram Mech4study

Schematic Of Electric Discharge Machining Edm Download Scientific Diagram

Electrical Discharge Machining Edm Of Reaction Bonded Silicon Carbide Rb Sic

Wire Edm Find Suppliers Processes Material

Electrical Discharge Machining Edm Process Explained Fractory

Optimization Of Machining Parameters And Wire Vibration In Wire Electrical Discharge Machining Process Mechanics Of Advanced Materials And Modern Processes Full Text

What Is Edm The Agb Portable Edm By Gordon Engineering

Parametric Optimization Technique In Wire Cut Electrical Discharge Machining An Overview Semantic Scholar